Because the world builds an increasing number of electrical automobiles and vehicles—and electrifies different modes of transit—a race is underway to construct the best, mean-and-green motor. The objective is a traction motor that’s at the least as highly effective, dependable, and light-weight as in the present day’s business commonplace rare-earth everlasting magnet synchronous motor. Nevertheless, rare-earth components like neodymium and dysprosium, that are required for probably the most highly effective magnets for the latter, additionally signify a significant choke level. Their mining and processing comes at an environmental value, and China holds a near-monopoly stake in them. Which is why the race to construct an EV motor with out rare-earths is so necessary. These initiatives don’t get as a lot consideration because the race for higher batteries and ever-more gargantuan battery factories, however they are going to be no much less important to the way forward for electrified transportation.

The motor R&D initiatives take a wide range of kinds, together with longstanding work to enhance induction motors and numerous unique sorts of synchronous motors, in addition to efforts to construct highly effective synchronous motors with everlasting magnets that don’t use uncommon earths.

“I’m a believer that this sort of materials is a recreation changer.” Ayman El-Refaie, Marquette College

Now a sleeper choice, synchronous reluctance motors, is getting a surge of curiosity, due to materials-science breakthroughs at GE Aerospace. GE is one in all a few firms growing supplies with a outstanding property: when uncovered to a powerful magnetic discipline, totally different areas of the fabric turn out to be magnetized at radically totally different ranges of depth—both not magnetized in any respect or very extremely magnetized. In a beautiful paper final yr, GE researchers reported that they’d used such a fabric, referred to as a dual-phase magnetic materials, to supply a rare-earth-free rotor for a synchronous reluctance motor that had spectacular traits.

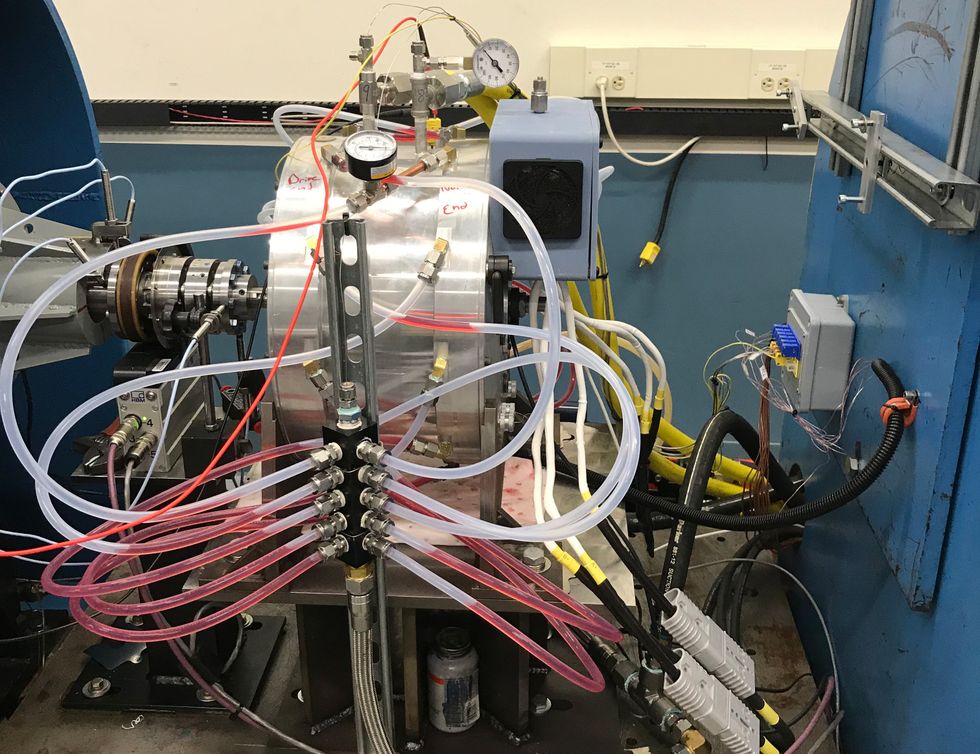

The 23-kilowatt experimental GE motor was examined on a dynamometer utilizing a torque meter—the grey, cylindrical merchandise with the fins at left. The translucent tubes comprise red-colored oil circulated to chill the motor.GE Aerospace Analysis

“I’m a believer that this sort of materials is a recreation changer,” says Ayman El-Refaie, an IEEE Fellow and professor {of electrical} and laptop engineering at Marquette College in Milwaukee, Wisc. El-Refaie originated the GE program in dual-phase supplies in 2005.

GE’s breakthrough materials

In assessments, the GE motor handily outperformed synchronous reluctance motors that had been kind of similar aside from having rotors fabricated with typical magnetic supplies. For instance, in a single trial, the motor with the dual-phase rotor had energy output of 23 kilowatts at 14,000 rpm; the comparable conventional-rotor machine may handle solely 3.7 kW. That dual-phase-equipped motor had a decent mass energy density of 1.4 kW per kilogram. (It fell in need of the anticipated worth of 1.87 kW/kg as a result of the prediction had been primarily based on attributes of lab-scale or simulated components relatively than manufacturing ones.) Electrical autos available on the market in the present day usually have motors with energy densities between 1.1 and three.0 kW/kg. The height effectivity of the GE motor was 94 %, on a par with the most effective motors used in the present day in industrial EVs.

To know the promise of dual-phase supplies, begin with some fundamentals about synchronous reluctance motors. As with different motors, they’ve a stator and a rotor. A rotating magnetic discipline is created within the stator. This spinning discipline magnetizes and engages the rotor, which is normally fabricated from a ferromagnetic alloy referred to as electrical metal. The rotor then spins due to a phenomenon referred to as magnetic reluctance, which is the property that causes a ferromagnetic materials to align itself with the traces of flux of a magnetic discipline. Because the stator discipline rotates, the magnetized rotor regularly tries to align itself with that rotating discipline, producing torque.

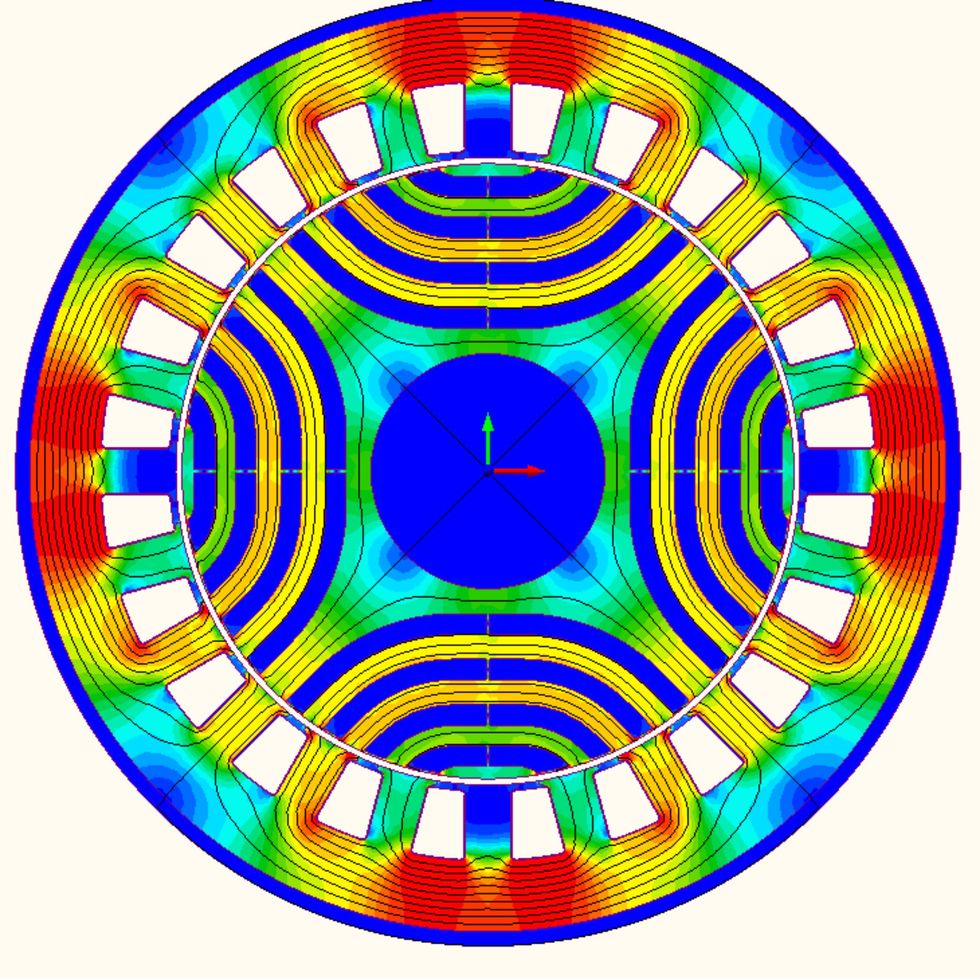

A four-pole rotor in a synchronous reluctance motor has areas which might be very extremely magnetized—proven in crimson—and others that aren’t magnetized (blue). This picture reveals the magnetization when the stator and rotor are aligned.Oak Ridge Nationwide Laboratory

One weak point of such a machine, nevertheless, entails the rotor. The magnetic interplay between the rotor and stator, which makes the rotor spin, is concentrated at evenly spaced positions, referred to as poles, on the rotor and stator. The magnetic discipline traces from a pole on the rotor should be strongly linked to a corresponding pole on the stator. Nevertheless, these discipline traces from the rotor poles tend to intervene with one another, which reduces the traces, or flux, accessible to hook up with the corresponding stator poles. “That may decrease the general torque that you may produce with the motor as a result of the torque is primarily as a result of that flux linkage between the motor poles within the rotor and the stator,” says Frank Johnson, one other veteran of the GE analysis crew on dual-phase supplies, and presently chief technical officer of Niron Magnetics in Minneapolis.

So to magnetically isolate the poles from one another, one choice could be to reduce buildings, referred to as bridges and posts, across the poles of the rotor. With much less magnetic materials, these buildings would produce much less flux and due to this fact much less interference. That’s truly not choice, although, as a result of minimizing these buildings would depart these areas slim and due to this fact mechanically weak. That weak point would vastly restrict the pace at which the rotor may spin, which might in flip restrict the motor’s energy.

However with a dual-phase materials, it’s potential to make the bridges and posts non-magnetizable (the technical time period is “non-permeable”), and likewise vast and powerful. That’s what GE did with its experimental motor.

No firm is but providing dual-phase magnetic supplies appropriate for the rotors of high-power traction motors. Nobody outdoors of GE Aerospace is aware of whether or not, or when, the corporate may license or manufacture its materials. (GE Aerospace declined to make a researcher accessible to be interviewed for this text.) A survey article printed in December within the Journal of Magnetism and Magnetic Supplies concluded that GE’s materials, which is produced in a course of referred to as high-temperature nitriding, “is probably the most developed technique for producing dual-phase magnetic metal. Because of the excessive manufacturability of manufacturing, the ultimate value of the product is aggressive in comparison with conventional electrical metal.”

Apart from GE, the one different firm recognized to be engaged on dual-phase magnetic supplies is Proterial (previously Hitachi Metals, which has been growing dual-phase magnetic supplies for the reason that Nineteen Nineties). College analysis applications investigating related applied sciences embody ones at Ufa College of Science and Know-how in Russia, Yeungnam College in Republic of Korea, Harbin Institute of Know-how in China, and the College of Sheffield within the U.Ok.

El-Refaie, at Marquette, says that GE’s dual-phase materials may very well be improved with additional improvement. For instance, the fabric’s most saturation flux density, a measure of how strongly magnetized the fabric can turn out to be, is 1.5 teslas—effectively beneath the two T restrict of bizarre electrical metal.

However technical advances are in all probability not the best hurdle to commercialization, he provides. “Whether or not somebody can deliver it to the end line, and set up a supply-chain for it, it’s not clear how that is going to occur,” says El-Refaie. “It’s not solely about GE. They must work with distributors in the event that they need to make it accessible for the broader technical market.”

“A major barrier will likely be discovering a metal producer prepared and capable of produce the rolled metallic sheet used to make the dual-phase rotor” materials, provides Johnson. “The alloy that we developed has very low value components, which paradoxically makes it a tough enterprise case to justify besides at very massive manufacturing volumes requiring massive quantities of capital tools.”

But when the fabric does go into mass-scale manufacturing, the advantages would go effectively past synchronous reluctance motors. Tasks at Marquette College, Yeungnam College, and Ufa College of Science and Know-how have demonstrated benefits of dual-phase supplies in everlasting magnet synchronous motors and electrical turbines.

“It’s not solely IPM (inside everlasting magnet motor) machines that may profit,” says El-Refaie. “It could actually have benefits in different sorts of machines as effectively, for various causes.”