AI and Drone Applied sciences Improve Bridge Security and Scale back Upkeep Prices

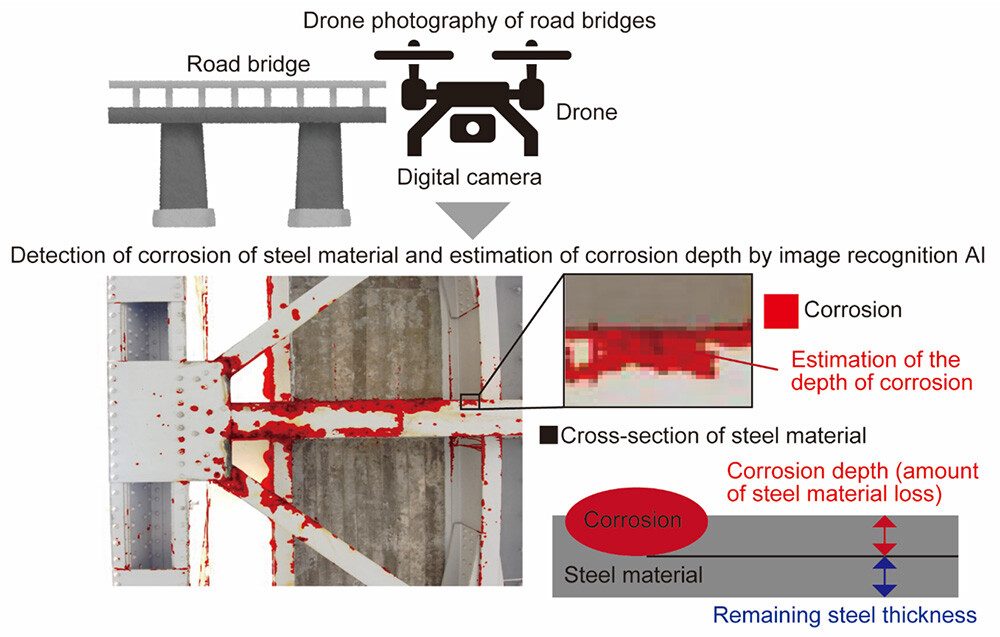

NTT Company (NTT) and NTT e-Drone Expertise Company have developed a cutting-edge technique to detect and restore corroded metal supplies on bridges utilizing a mix of AI picture recognition and drones. This new strategy goals to beat the constraints of conventional visible inspections, guaranteeing the security and longevity of metal buildings worldwide. By using this know-how, the businesses count on to considerably cut back the associated fee and energy of sustaining essential infrastructure like bridges.

Addressing the Challenges of Corrosion Detection

Corrosion in metal supplies, significantly in hard-to-reach areas, presents important challenges for the upkeep of bridges. Conventional inspection strategies usually depend on visible inspection, making it troublesome to precisely assess the depth of corrosion. As NTT explains, “It may possibly detect corrosion and estimate the corrosion depth on the identical time by imaging with drones and AI inspection, which has been troublesome to do with visible inspection by inspectors.” By automating the method with drones and AI, inspectors can extra simply detect harm and estimate corrosion depth with out the necessity for pricey scaffolding or ultrasonic probes.

The Federal Freeway Administration has highlighted the difficulties in corrosion detection, noting that check outcomes will be inconsistent on account of various operator expertise and tools sensitivity. To handle these points, NTT has built-in AI into drone-based imaging methods, permitting for each detection and measurement of corrosion in metal bridges. This mix of applied sciences might enhance the effectivity and accuracy of bridge inspections, finally guaranteeing the structural integrity of getting old infrastructure.

Actual-World Utility in Japan

NTT and NTT e-Drone Tech examined their AI and drone-based resolution on a bridge in Kumagaya Metropolis, Japan. The drones captured photos of the bridge, which had been analyzed by the AI to detect areas of corrosion and estimate the depth of harm. In line with NTT, this know-how has the potential to cut back inspection prices whereas growing the accuracy of corrosion detection.

“Enchancment of labor effectivity and diminished upkeep prices through the use of an ultrasonic gadget to measure the quantity of loss within the metal cross part of corroded areas utilizing drone imaging and AI inspection,” mentioned NTT in a press launch. By automating these duties, NTT goals to make it simpler and cheaper for infrastructure managers to take care of bridges and different metal buildings.

Future Outlook and Growth

NTT plans to increase using this know-how past bridges to incorporate different infrastructure equivalent to metal towers and guardrails. By persevering with to refine the accuracy of the AI system and enhance the effectivity of drone operations, NTT hopes to introduce this resolution as an inspection assist know-how by fiscal 12 months 2025.

NTT’s purpose is to contribute to a sustainable society by decreasing the rising prices of infrastructure upkeep and guaranteeing the security of essential buildings. The corporate will use the outcomes of its demonstration in Kumagaya Metropolis to guage the practicality of the know-how and discover methods to use it to a broader vary of infrastructure services.

Learn extra:

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, an expert drone companies market, and a fascinated observer of the rising drone business and the regulatory setting for drones. Miriam has penned over 3,000 articles centered on the industrial drone house and is a world speaker and acknowledged determine within the business. Miriam has a level from the College of Chicago and over 20 years of expertise in excessive tech gross sales and advertising and marketing for brand new applied sciences.

For drone business consulting or writing, Electronic mail Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife right here.